Approximately 6 Million Tonnes of Plastic Waste goes un-recycled every year in India.

The idea of reusing products has been around for quite some time. Though the plastic recycling process has its limitations and flaws, it is a constantly evolving process. Of the 7 major types of plastics that are largely available, these four are most commonly recycled:

- PET- Polyethylene Terephthalate

- HDPE- High Density Polyethylene

- PVC- Polyvinyl Chloride

- LDPE- Low Density Polyethylene

Like all recycling processes, the plastic recycling process refers to the process of re-using plastic waste by means like reprocessing. Due the low biodegradability of plastics, understanding of the recycling process has become essential.

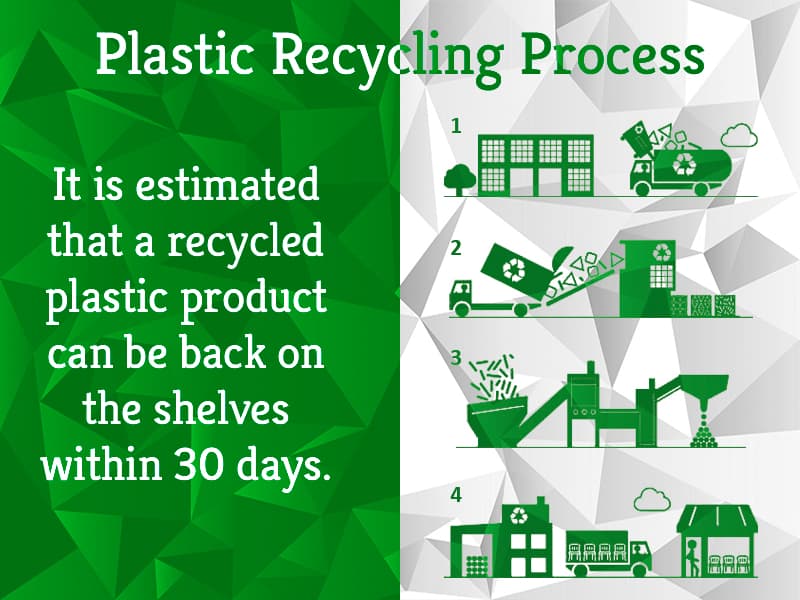

Plastic Recycling Process

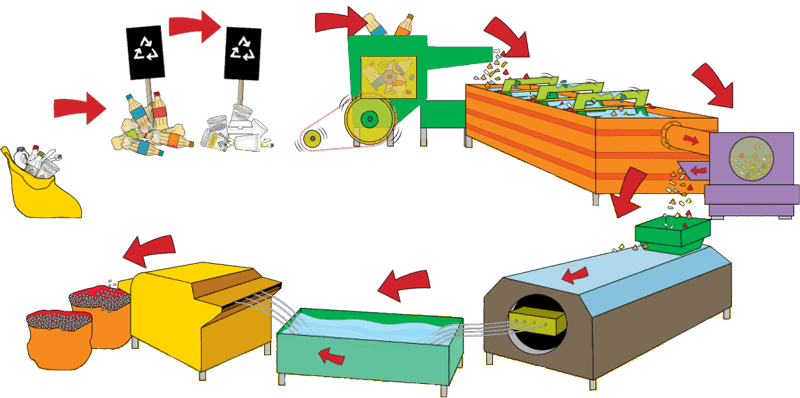

The recycling processes can be broken down into 7 distinct steps :

Step 1 – Collection

Plastic waste is growing by the ton every day. Using a country-wide network for collection of plastic waste through rag pickers, waste collectors and waste dealers and recycling enterprises this plastic waste is collected and brought to the Sorting facilities for further processing.

Step 2 – Sorting

This second step is the most crucial one as he actual plastic recycling process starts with Sorting. Sorting of different plastics occurs based on:

- Color

- Resin Content

- Plastic Recycling Code

Sorting helps identify and eliminate contaminants. The process may employ manual methods or the use of specifically designed machines.

Step 3 – Shredding

Once the recyclable plastics have been sorted, they go through the shredder. The shredder grinds and cuts the plastics into tiny pieces. After going through shredding, heavier and lighter plastics are separated using specially designed machines. This separation helps segregate different plastics.

Step 4 – Cleaning

The process of Sorting and Shredding ensures that the correct types of plastics are being processed and assorted together for further processing. After a complete separation, the flakes or chunks are then washed thoroughly with detergents to remove the remaining contamination.

Following the cleaning process, the plastic flakes are subjected to moderate heat so that they can dry.

Step 5 – Melting

Post drying, the plastic flakes are melted down under regulated temperatures. The regulation of temperatures ensures that the plastics are melted without getting destroyed. On melting, these plastics are extruded and resized to be processed in to granules which will later be compressed into pellets.

Step 6 – Pellet Making

To enable the plastics to be reusable processed granules are compressed into tiny pellets. These pellets are also known as nurdles. Pellets also enables in storing similar types of plastics based on color, types of resin along with easy distribution.

Step 7 – Re-Using

It is important to note that, pellets recycled from particular types of plastics cannot to be re-used to make the same kinds of plastics. Instead they are re-purposed and redesigned in to other useful products.