Approximately only 45% glass waste gets recycled in India every year.

Because glass does not decompose, recycling it is crucial for sustainability. Glass is almost 100% recyclable and can be recycled endlessly without loss in quality or purity. Recycling glass helps conserve raw materials, reduces energy consumption, and minimises landfill waste. With proper sorting and processing, glass recycling is key in building a circular economy. Embracing glass recycling benefits the environment and supports sustainable manufacturing practices.

How is Glass Recycled?

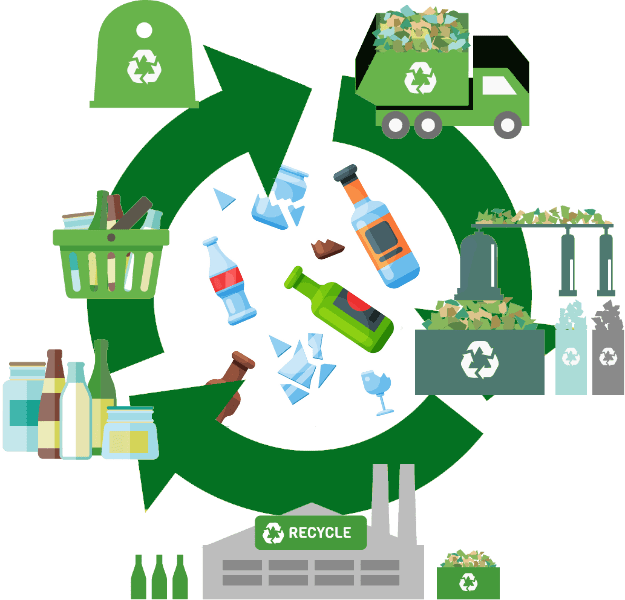

Recycling glass involves a systematic, multi-step process transforming used glass items into reusable raw material. The goal is to create high-quality recycled glass products while minimising contamination and waste. Effective glass waste management begins at the collection stage and continues through cleaning, decolourising, and remanufacturing, ensuring minimal environmental impact and maximum reuse potential.

Glass Recycling Process

With some material-related variations, the glass recycling process has the following steps:

Step 1 – Collection

Different glass items end up in waste piles and recycling bins after serving their purpose or breaking. Proper glass disposal at the household and commercial levels plays a vital role in streamlining this collection process. Encouraging responsible glass disposal habits helps prevent glass from ending up in landfills and ensures it enters the recycling stream efficiently. These are collected using a country-wide network which includes:

– Rag-Pickers

– Waste Collectors

– Waste Dealers and

– Recycling Enterprises

Upon collecting glass waste, it is transported to the nearest sorting facilities for further processing.

Step 2 – Sorting

The addition of other chemicals and slight variations in manufacturing processes prepare different types of glasses. Because of this, glass waste is sorted based on colour to increase recycling efficiency.

Step 3 – Cullet Production

Once the waste glass is sorted, it is then turned into tiny pieces also known as ‘cullets’ by means of crushing and grinding. Cullets can formed of different sizes depending on the requirements.

Step 4 – De-Contamination Process

All types of waste including glass waste (or in this case cullets) are riddled with different types of contaminants. If contaminants are allowed to remain in the glass cullet, the quality of recycled glass can be affected like having structural defects. In order to recycle glass properly, it is imperative to get rid of these contaminants.

Different contaminants can be processed in the following manner:

– Metallic contaminants are passed through a magnet.

– Paper and plastic contaminants are picked up manually or through an automated process.

– Ceramic contaminants are removed via sieving, where finely ground glass cullet is made to pass through various screens.

If, however, ceramic contaminants do pass through the various screens together with the glass cullet, the quality of the recycled glass will be affected. Ceramic contaminants in glass can lead to structural defects.

Step 5 – De-colourising and Dyeing

The glass cullet does not necessarily match the desired colour of the end product. Therefore, to produce recycled glass of the desired colour, the glass cullet must undergo glass decolourising in the glass recycling process, followed by dyeing.

The decolourising process involves oxidising the melted glass cullet.

For Green Glass:

The oxidation process turns the deep dark green color to yellow-green color. A chemical known as manganese oxide is then mixed with the glass cullet to it grey. The grey base is usually used as the primary color to which various other coloring dyes or agents are added to develop glass of various colors.

For Brown or Amber-Colored Glass:

Zinc oxide is added instead to oxidise the brown glass cullet to blue or green cullet, depending on the quantity of zinc oxide added and the richness of the brown or amber-colored glass being recycled.

For Clear Recycled Glass:

Erbium oxide and Manganese oxide are added to the glass cullet to help clear all the colors from the glass cullet.

Some of the most commonly used colouring agents for dyeing of recycled glass include:

– Borax

– Potassium Permanganate

– Zinc Oxide

– Erbium Oxide

– Cobalt Carbonate

– Neodymium Oxide

– Titanium Dioxide.

Step 6 – Making recycled glass products

To make recycled glass products, glass cullet, clear or colored, is melted and moulded into the desired products, such as bottles, jars, containers, etc.

1 comment